The field of electronics has long been associated with rigid circuits and permanent materials, but a quiet revolution is brewing at the intersection of biomedical engineering and sustainable technology. Researchers are now pioneering biocompatible and biodegradable electronic packaging that could transform everything from temporary medical implants to eco-friendly consumer devices. This emerging technology promises to address two critical challenges simultaneously: reducing electronic waste and enabling seamless integration with biological systems.

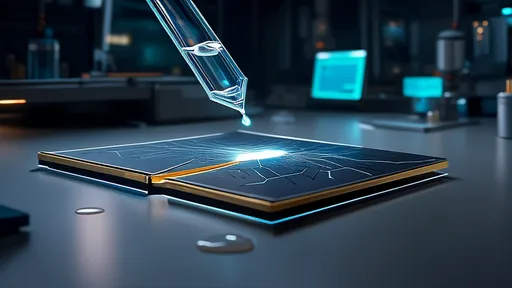

Traditional electronic packaging relies on materials like epoxy resins, ceramics, and metals that persist in the environment indefinitely. As the world grapples with mounting e-waste, scientists have turned to nature for inspiration. Polylactic acid (PLA), silk fibroin, and cellulose-based composites are showing remarkable potential as substrates for electronic components. These materials maintain functionality during their operational lifespan but can safely degrade when their purpose is served. The implications are particularly profound for medical applications where secondary removal surgeries could be eliminated.

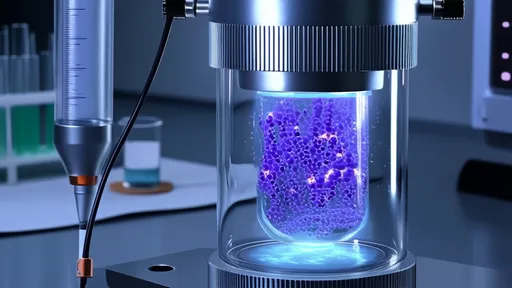

Medical device innovation stands to benefit enormously from these advancements. Consider cardiac monitoring patches that dissolve after postoperative recovery or neural interfaces that gradually break down as nerve tissue regenerates. Researchers at leading institutions have demonstrated fully biodegradable pressure sensors capable of monitoring intracranial pressure following traumatic brain injuries. These devices transmit critical data wirelessly before harmlessly absorbing into cerebrospinal fluid, eliminating risks associated with permanent implants.

The environmental potential extends far beyond healthcare. Consumer electronics manufacturers are exploring transient packaging for devices with planned obsolescence. Imagine smartphone cases that compost naturally or wearable fitness trackers with dissolvable circuits when upgraded. Such applications could dramatically reduce the 53 million metric tons of e-waste generated globally each year. Early prototypes have shown particular promise in agricultural technology, where soil-degradable sensors monitor crop conditions throughout a growing season before becoming fertilizer components.

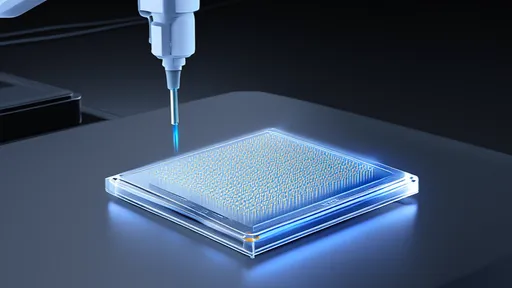

Material science breakthroughs underpin this technological shift. Engineers have developed water-soluble conductive inks using magnesium and tungsten that maintain stable electrical properties until triggered dissolution. Barrier layers made from engineered proteins control degradation rates with precision, allowing designers to program operational lifetimes from days to years. Perhaps most remarkably, some research teams have created electronic components that actually nourish surrounding tissue as they break down, releasing beneficial ions like magnesium during degradation.

Despite the excitement, significant challenges remain. Achieving reliable performance across varying environmental conditions requires careful material tuning. Humidity, pH levels, and microbial activity all influence degradation rates unpredictably. Long-term biocompatibility testing presents another hurdle - while materials may be non-toxic initially, their breakdown products must also prove harmless. Regulatory pathways for such hybrid medical-electronics devices remain undefined in most jurisdictions, potentially slowing clinical translation.

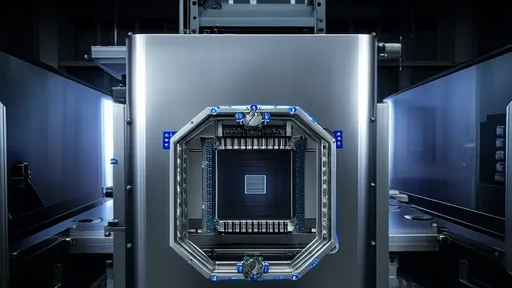

The commercial landscape is beginning to reflect this technology's potential. Several startups have emerged with specialized focus areas, from absorbable neurostimulators to compostable RFID tags for sustainable packaging. Established electronics firms are forming unusual partnerships with biotech companies and even agricultural producers to develop supply chains for these novel materials. Investment trends suggest the biodegradable electronics market could exceed $1 billion within five years, driven equally by environmental regulations and healthcare demands.

Looking ahead, the convergence of biology and electronics appears inevitable. As material libraries expand and manufacturing techniques adapt, we may see entire categories of transient electronics emerge. Future applications could include edible dosage-tracking circuits in pharmaceuticals or building materials with embedded sensors that degrade as construction settles. The paradigm shift from permanent to purposeful impermanence in electronics design represents one of the most promising avenues for sustainable technological progress.

What makes this field particularly compelling is its interdisciplinary nature. Progress depends equally on advances in polymer chemistry, electrical engineering, and biological integration. Academic programs are beginning to train specialists who can bridge these traditionally separate domains. Conferences that once catered to distinct audiences now regularly feature joint sessions on bio-integrated electronics, signaling a fundamental reshaping of both industries.

The road ahead will require careful navigation of technical and ethical considerations. Questions about data security in dissolving devices, appropriate degradation timelines, and material sourcing sustainability all demand thoughtful solutions. Yet the potential rewards - both for planetary health and human wellbeing - make this one of the most consequential frontiers in modern materials science. As research accelerates, biodegradable electronics may soon transition from laboratory curiosity to therapeutic reality and environmental necessity.

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025